Overview

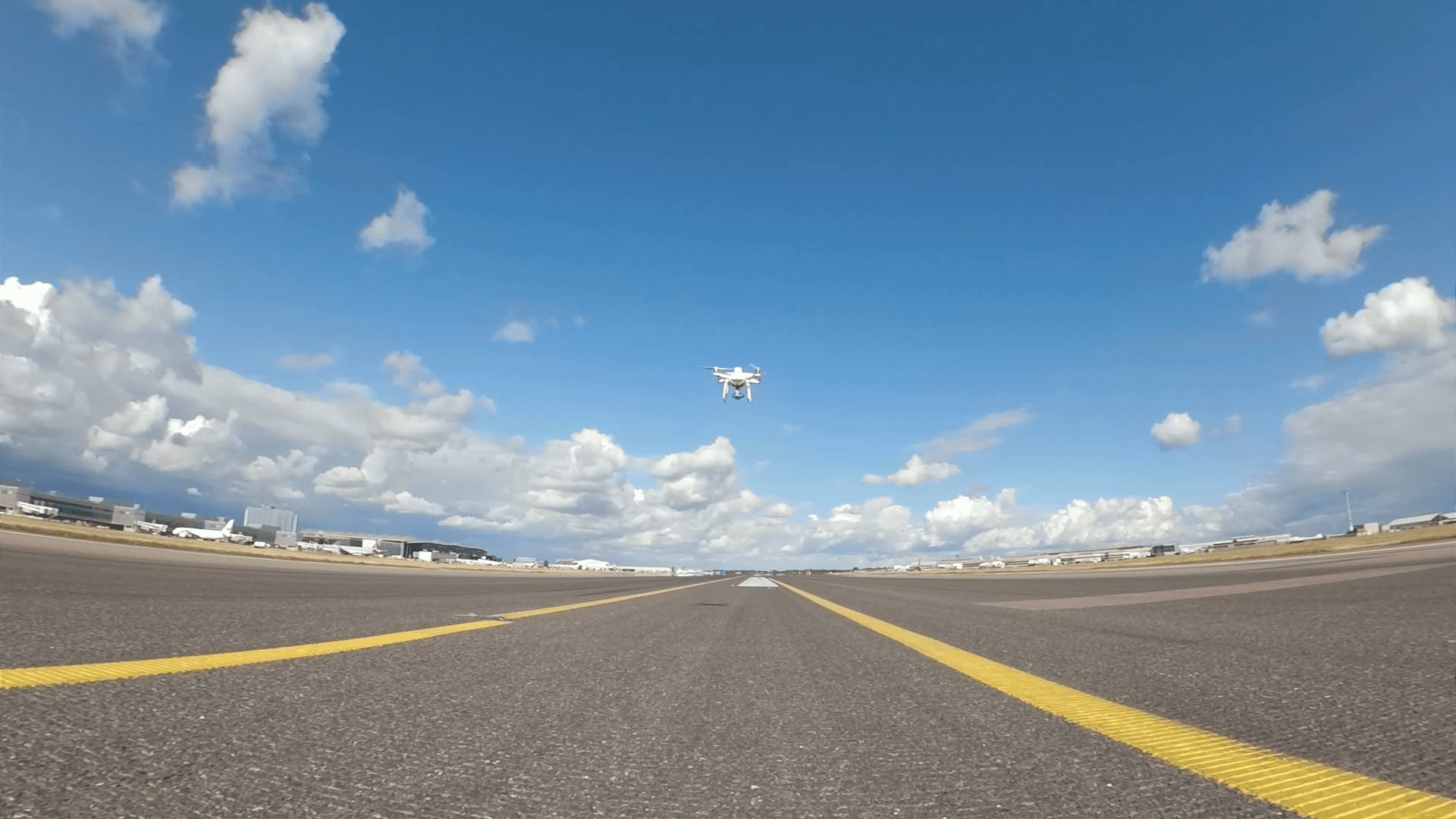

Sky-Futures™, an ICR company, is a distinguished leader in UAS inspection services, catering to global clients across industries including; oil and gas, renewables, marine and port services, civil infrastructure and telecommunications. With over a decade of experience in the industry, Sky-Futures™ were among the pioneers to introduce unmanned technology to the oil and gas inspection market, consistently deploying cutting-edge innovations to meet the evolving needs of our clients.

UAS inspections are up to 85% faster than traditional inspection techniques, capable of operating in winds up to 29 knots, reducing the need for direct human exposure while gathering high-quality, measurable, and dynamic inspection data. Remote Inspection is also proven to be up to 85% more cost-effective than traditional methods, as they don’t require the shutdown of platforms and are operated by a lean two-man team.

Track record

Our extensive customer base spans across more than 42 countries, fostering a wealth of experience across onshore and offshore operations. With an international presence covering the UK, USA, South America, Europe, Africa, Middle East, South East Asia, and APAC, we are well-versed in navigating the regulatory and logistical intricacies that enable us to deliver unmanned technology solutions on a global scale.

Our inspection teams consist of highly experienced remote pilots and qualified inspection engineers as sensor operators.

Our services

- Visual inspection and survey

- External and internal inspection

- Fugitive emissions survey covering multiple gases in line with OGMP 2.0

- Confined space inspection

- Flare tip inspection

- Wind turbines

- DROPS and PDO survey

- Storage tanks

- Digital twin and orthomosaic capability

- Ultrasonic testing – class-leading sensor and aircraft

- 3D modelling that combines tripod-mounted Lidar scanning with aerial datasets

- Payload technologies include; visual, thermal, surveying, gas detecting, live streaming, multispectral and NDT

Benefits

Reduce risk to personnel through UAS inspections and avoid working at height

85% more cost effective than traditional inspection methods

Quality data and analysis through secure cloud based reporting